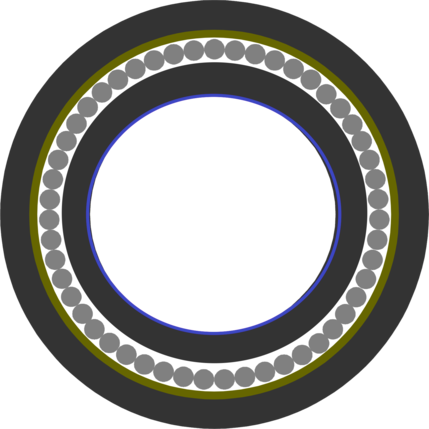

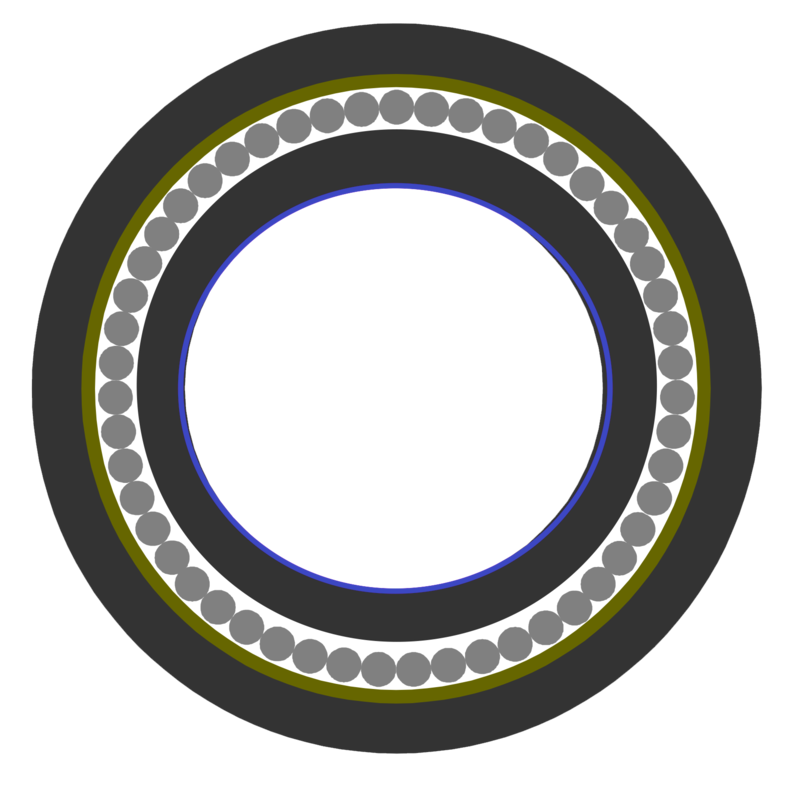

Microduct UWS 1x12/10mm BLACK HDPE OD 21.3mm 2000m/dr.

| Product code | 88028012 | |

|---|---|---|

| Sales unit | Meter | |

| ETIM-Class | EC001474 |

-

Product specifications

Microducts are designed for long term protection of fiber optical cables and are especially suitable for installation of micro cables. The underwater armored microducts are suitable for under water installation like lakes and river crossings. It attains its mechanical robustness and functional performance through its steel wire armour (SWA) reinforcement. Needs no further protection at under water or underground installations. The primary duct are made of high-density virgin polyethylene (HDPE). Every microduct has a permanent, co-extruded silicone compound inner liner giving a coefficient of friction of less than 0,1.

- Measurements

- Documents

-

Technical Specifications - Single Ducts

- Technical Specifications - Bundle

-

Mechanical Characteristics

- Other variants